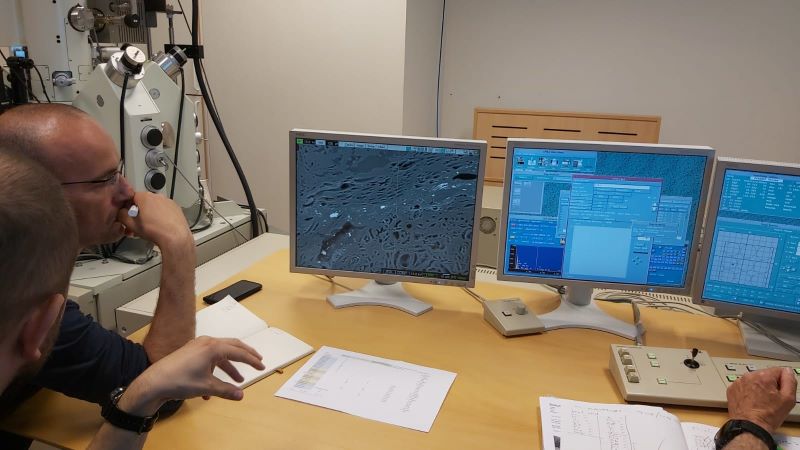

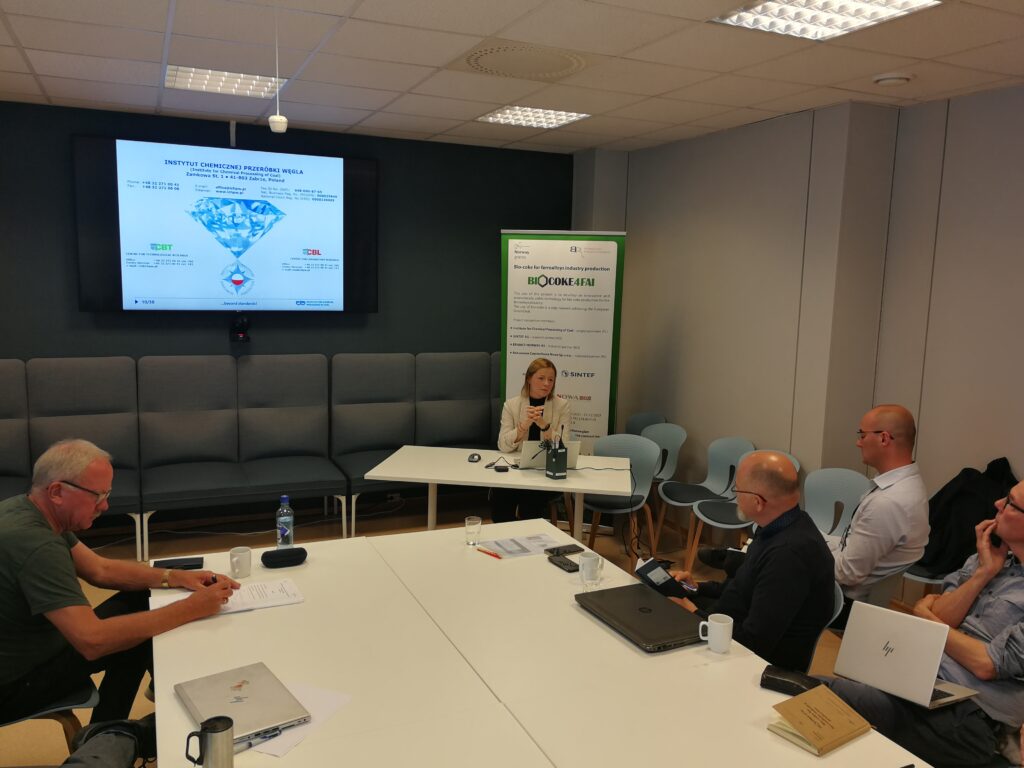

From 1 to 3 June, IChPW employees Michał Rejdak and Małgorzata Wojtaszek – Kalaitzidi took a study visit as part of the BioCoke4FAI project. The study visit took place at the Norwegian research Institute SINTEF in Trondheim, which is also the research partner of the project. The visit was supervised by Michał Książek from SINTEF. As part of the visit, IChPW employees participated in technological research of bio-coke produced at the Institute. The research included parameters important for the production of manganese ferroalloys, such as electrical resistance, reactivity to CO / CO2 gas (SINTEF method), studies of the microstructure of biocokes by EPMA (electron microscopy) and slag reactivity.